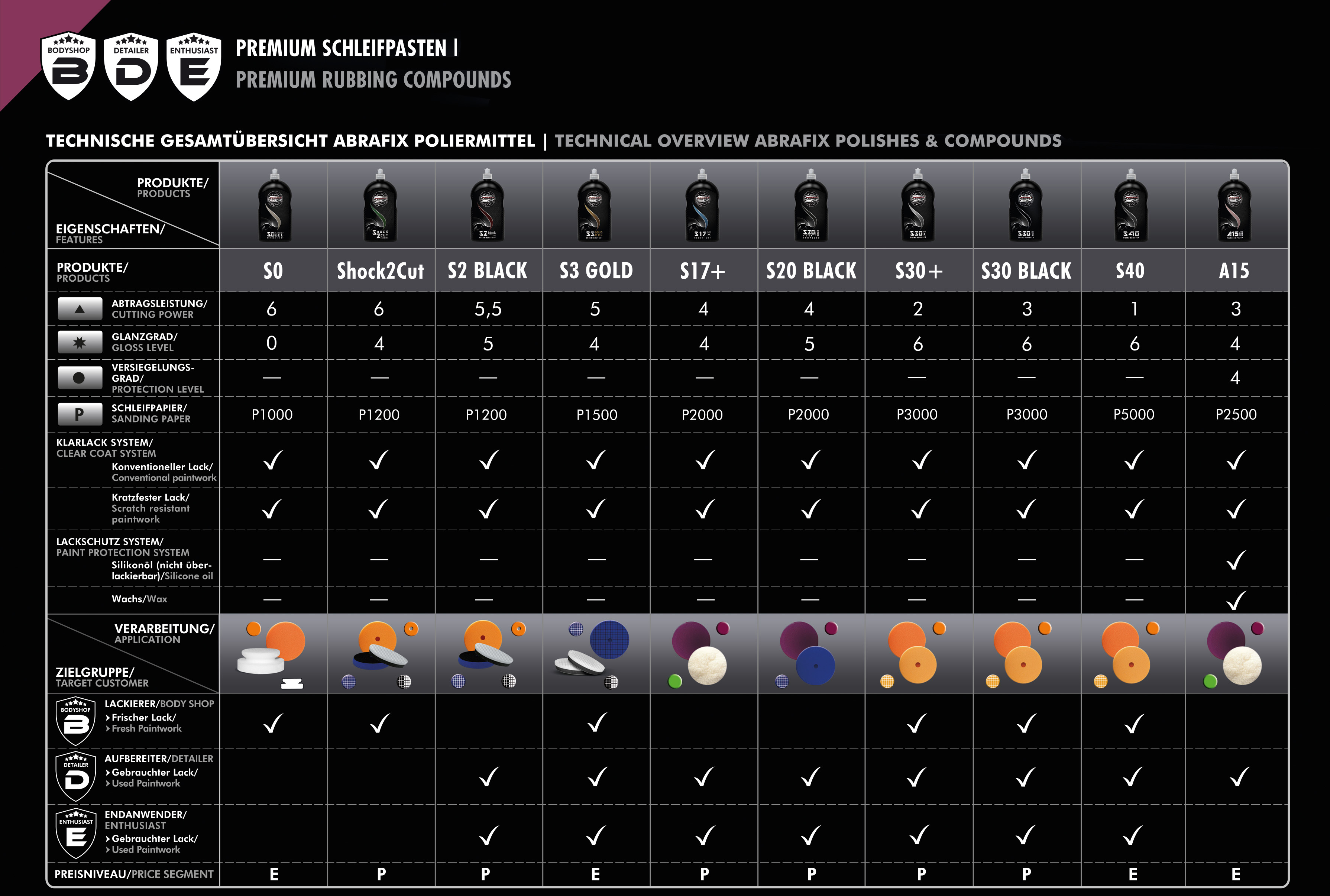

S3 GOLD XXL Extra-Heavy-Cut

| Capacity in g: | 500g |

|---|---|

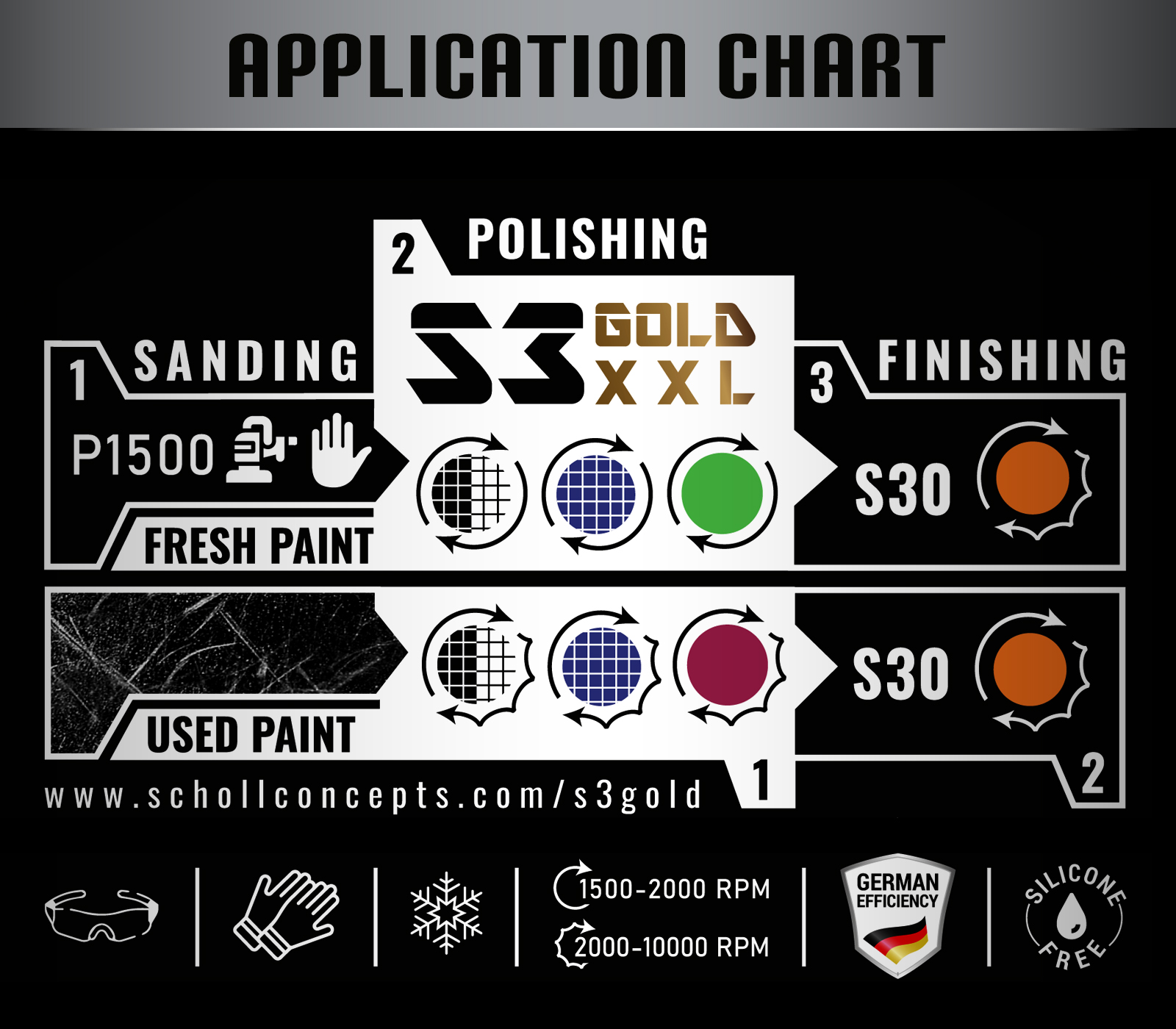

| Customer: | Detailer, Enthusiast, Bodyshop |

| Cut: | 5 of 6 |

| Gloss: | 4 of 6 |

| Pad recommendation: | SpiderPad Navy-Blue, HandPuck White, Sandwich-SpiderPad Black/White |

| Sanding Paper: | P1500 |

Login

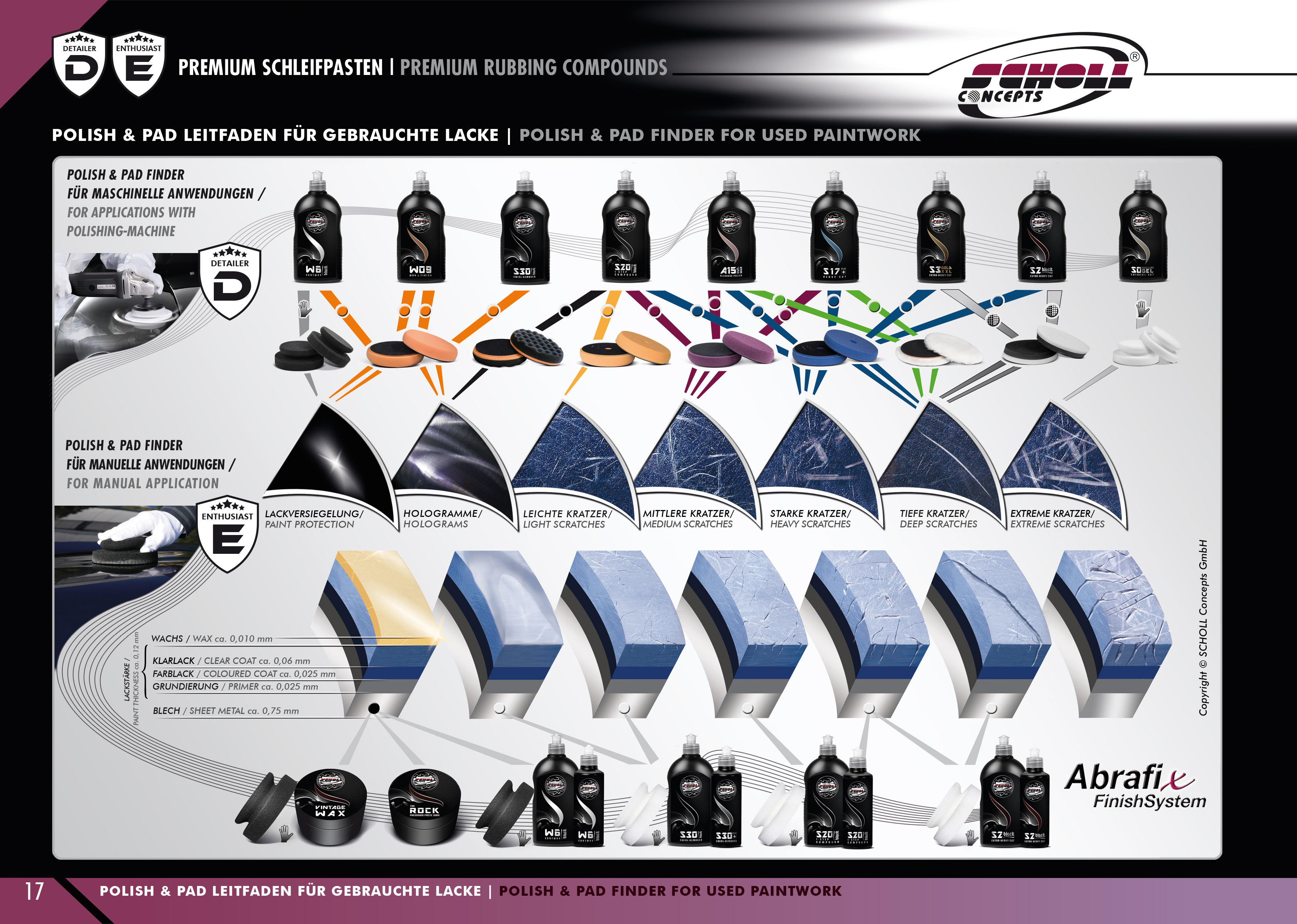

Polishing pads are made up of different materials and come in different shapes and sizes. The choice of the right kind of pad, however, depends mainly on the application and required cut. Lambskin polishing pads have given rise to one of the most common misconceptions we have about polishing pads. The lambskin pad is the most abrasive polishing pad with the highest cut that we know of. The differences between the various polishing pads are as follows:

ABRASIVE EFFECT

EXTRA-COARSE (1)

Premium SOFTouch Topwool

Premium polishing pad made from 100% natural wool and integrated orange foam interface layer, for maximum cutting performance on fresh and worn paint surfaces.

COARSE (2)

Sandwich SpiderPad (black/white)

Innovative foam pad with calibrated surface and double-layer structure for maximum cutting performance and low heat build-up on fresh paint surfaces.

COARSE (3)

SpiderPad (navy-blue)

Firm, reticulated premium polishing pad. A brand new, unique heat-resistant foam composition provides a steady and consistent cutting performance.

MEDIUM (4)

Polishing pad (purple)

Superior, firm foam pad with a coarse porous structure, ideal for paint detailing applications. The tear-resistant, reticulated foam composition provides maximum durability.

FINE (5)

All-purpose sponge (orange)

This all-purpose, semi-firm pad with a fine, closed-cell foam structure is ideal for final finish and sealing applications.

FINE (6)

SpiderPad Neo (yellow)

This fine porous, reticulated hybrid pad with a calibrated surface was designed for the efficient application of the NEO Polymer Protection. Ideal for removing holograms.

EXTRA FINE (7)

SOFTouch-Waffle Pad (black)

Extremely fine and soft foam pad with an extra orange interface layer for controlling contact pressure on the surface to be polished.