C-ROCK Permanent Ceramic Coating Bundle

| Capacity in ml: | 30 ml |

|---|---|

| Customer: | Detailer, Enthusiast |

Login

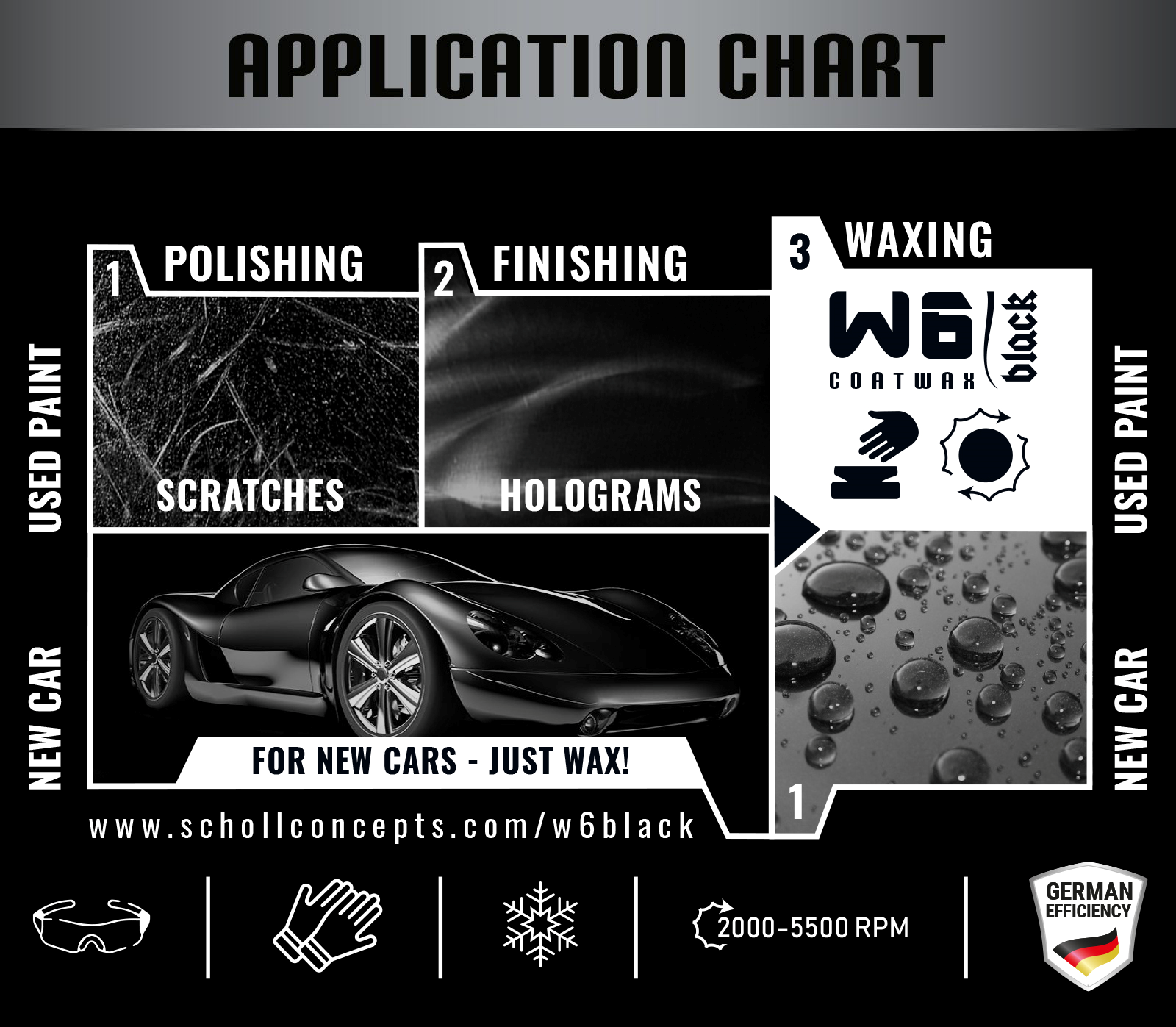

STEP 1 | PREPARATION AND CLEANING

After completing polishing work, the surface should always be checked for paint defects (scratches). Otherwise, these will be encased or enclosed by the sealant and will be difficult to remove afterwards. Once the surface is ready, use PREPARATOR Sealing PrePare (Prod. No.: 11083) to pre-clean all the vehicle surfaces on which the C-ROCK Permanent Ceramic Coating is to be applied. To be on the safe side, this process can be repeated once. All oils, greases, adhesive residues, silicones, and waxes must be removed!

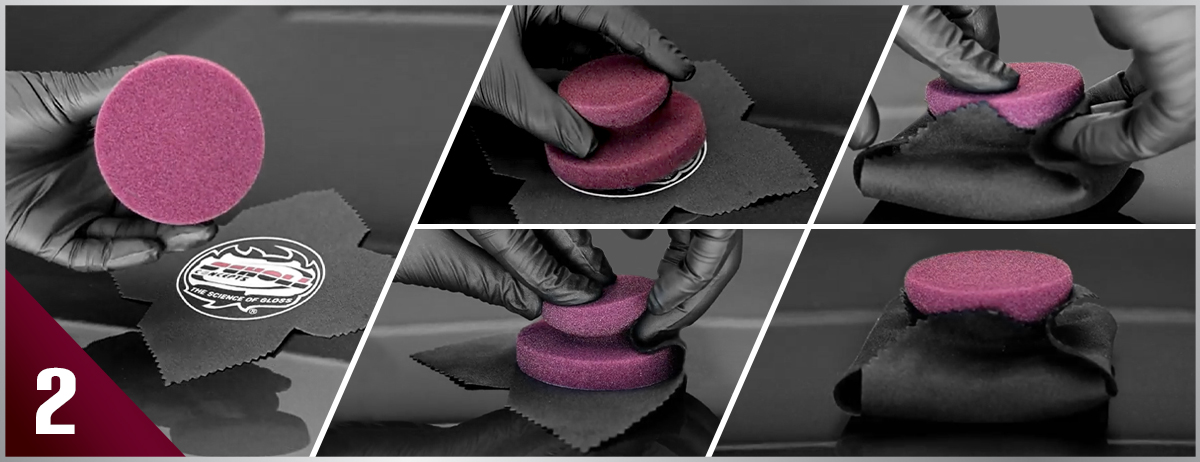

STEP 2 | CONNECTING THE APPLICATOR (HAND-PUCK) WITH THE MICROFIBER CLOTH

The first step is to wrap the microfiber cloth around the application sponge. Position the applicator centrally on the SCHOLL Concepts logo on the microfiber cloth and fix all four ends of the cloth in the foam notch.

STEP 3 | APPLICATION OF C-ROCK PERMANENT CERAMIC COATING TO THE MICROFIBER CLOTH

The bottle of C-ROCK Permanent Ceramic Coating must be shaken well before each use. Apply 5-10 drops to the large, microfiber-coated side of the applicator.

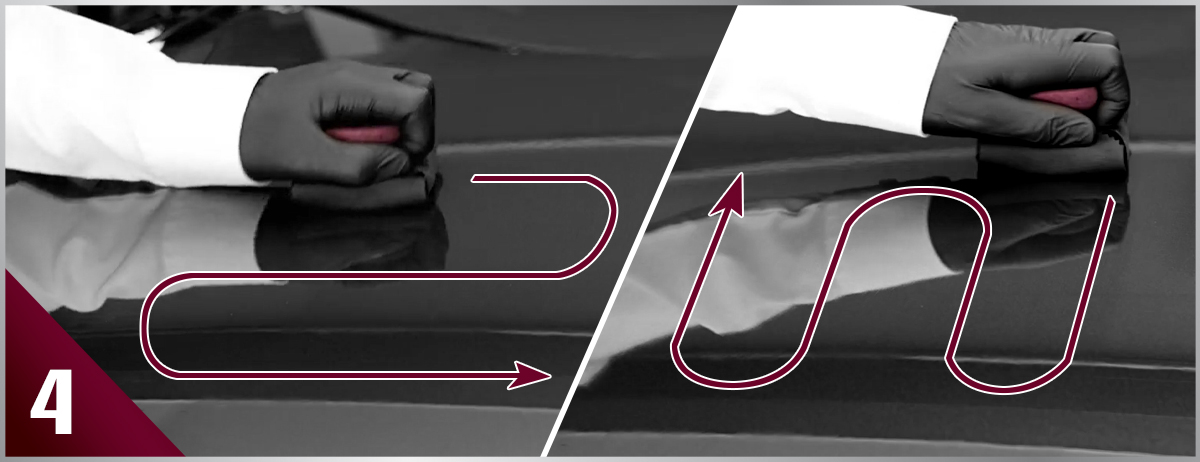

STEP 4 | APPLICATION ON THE PAINT SURFACE

Then use the applicator to apply the liquid evenly on the paint surface in a criss-cross pattern. No area should be omitted and a homogeneous film should be formed. The crosswise movement itself should not exceed an application area of more than 60×60 cm.

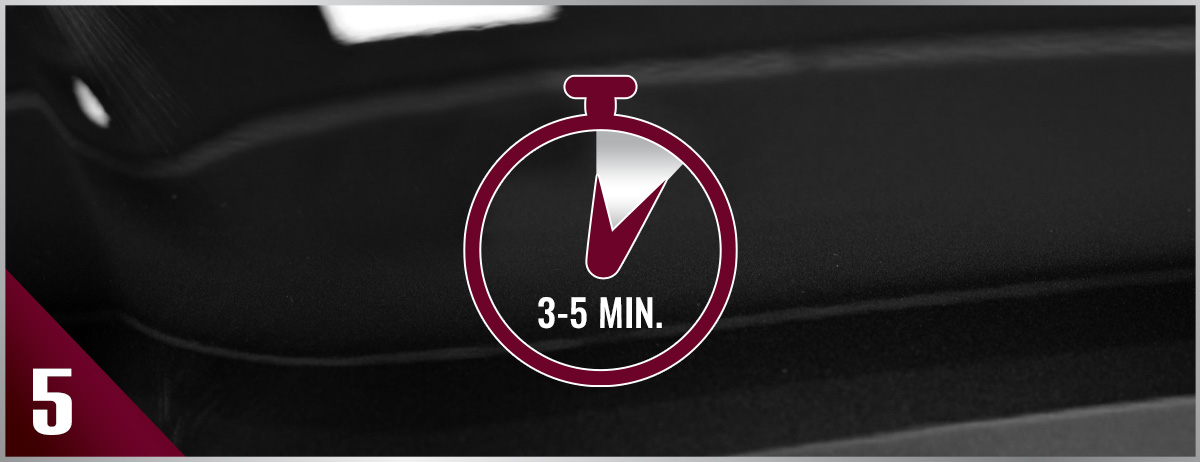

STEP 5 | TREATMENT TIME

After application, the C-ROCK Permanent Ceramic Coating needs a short treatment time of about 3 – 5 minutes. For colder environments or surface temperatures, we usually recommend a longer treatment time of up to 5 – 6 minutes.

STEP 6 | REMOVAL OF LIQUID RESIDUES

Once the treatment time is over, the residues are removed with the help of a microfiber cloth (lint-free), such as our MicroPLUS polishing cloth 40×40 cm red (Prod. No.: 22446). Once all liquid residues have been removed, the application step is complete.

STEP 7 | RESTING/DRYING PHASE

After the application and subsequent removal of the liquid residues, the drying phase begins. During this phase, you should not move your vehicle. Let it rest for 24 hours. The most important hours are the first 9. Within this time frame, your vehicle should not be exposed to any weather. A wind-protected and roofed parking place would be advantageous. After 9 hours, the most sensitive phase is over. Nevertheless, you should wait 24 hours before moving your vehicle in order to achieve a weather-resistant degree of hardness. You can start with the first wash of your vehicle after 7 days.

Headquartered in Remseck, Germany, SCHOLL Concepts GmbH has been catering to the requirements of the car care industry for 60 years by providing premium, innovative car care and maintenance systems for the automotive repair and paint industry. Our commitment and passion to create the perfect paint finish has made us one of the global leaders in innovative and customised solutions and the leading experts for comprehensive paint finish solutions.

Our corporate culture focuses on providing premium products and services. To implement this strategy, we pursue an integrated approach. High-grade, innovative and unique products and ideas can only develop when this philosophy is an integral part of our corporate culture and all processes, facilities and equipment are geared to meet the highest quality demands. Thanks to their distinctive brand names, among other features, our pre- mium products are easily identifiable and enjoy a high level of awareness.

WE DEVELOP & PRODUCE YOUR POLISHES & PADS UNDER YOUR BRAND NAME

Our life is defined by 3 spatial dimensions and as biological beings we developed in 3 dimensions. So what could be more natural than viewing our business in 3 dimensions? Get to know our unique B2B concept: SCHOLL Concepts does not just develop high quality and individual premium products but also an intelligent overall concept for their effective commercialization.