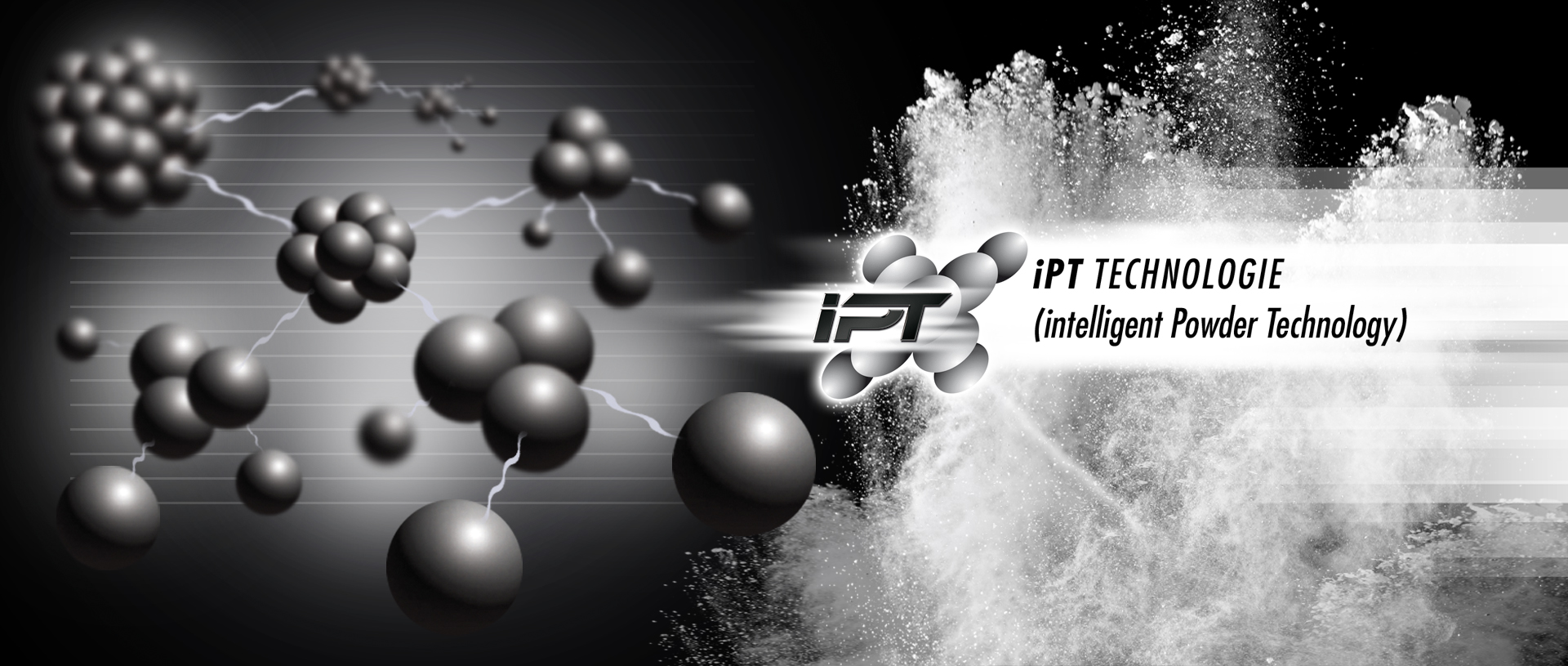

IPT Technology

The abrasive grain used in our high performance compounds is based on a high-purity, white aluminium oxide powder that removes weathered and scuffed paint surfaces in only one operation, creating a brilliant physical mirror-like gloss. Conventional polishing compounds would require two or more polishing steps to achieve such results. This is the outcome of decades of research and development that have been put into the optimisation of our powder technology. The highly efficient and intelligent iPT powder generation is used in most of our compounds.

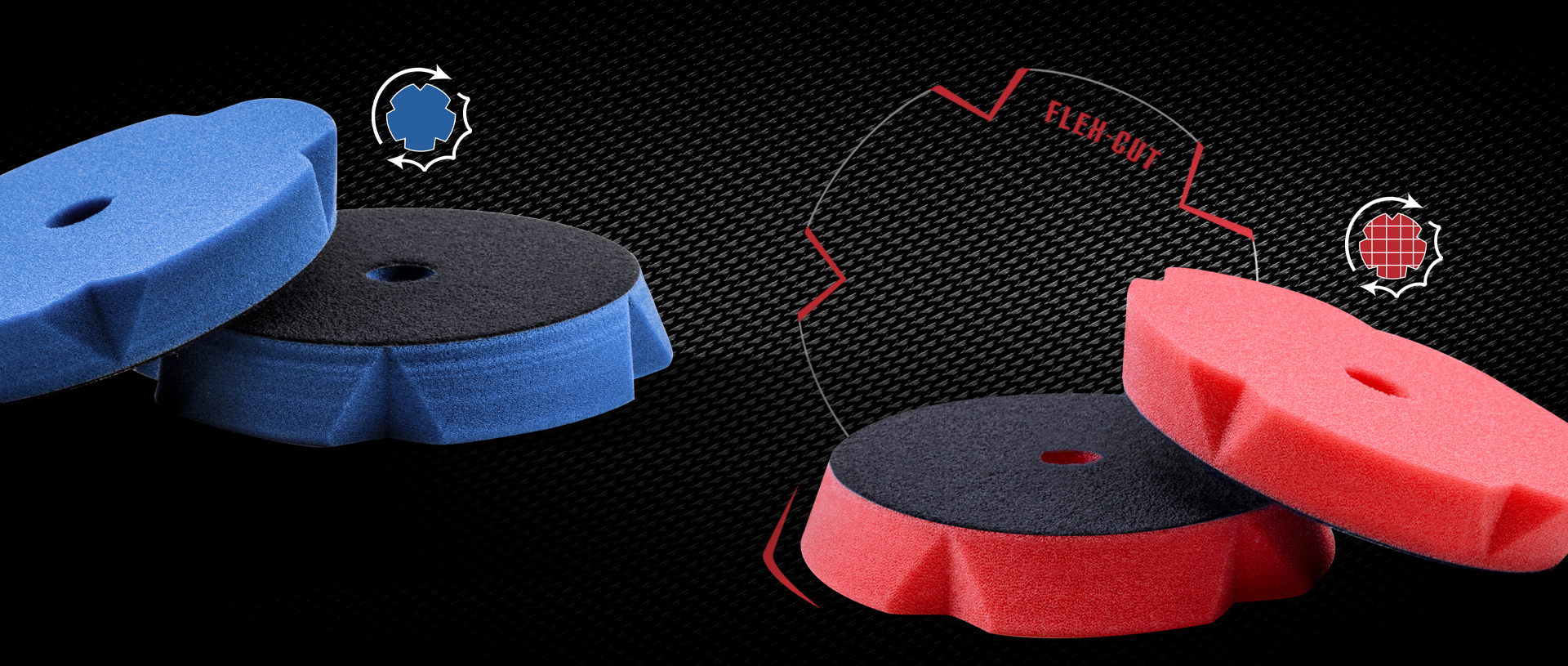

A STATE-OF-THE-ART MANUFACTURING FACILITY

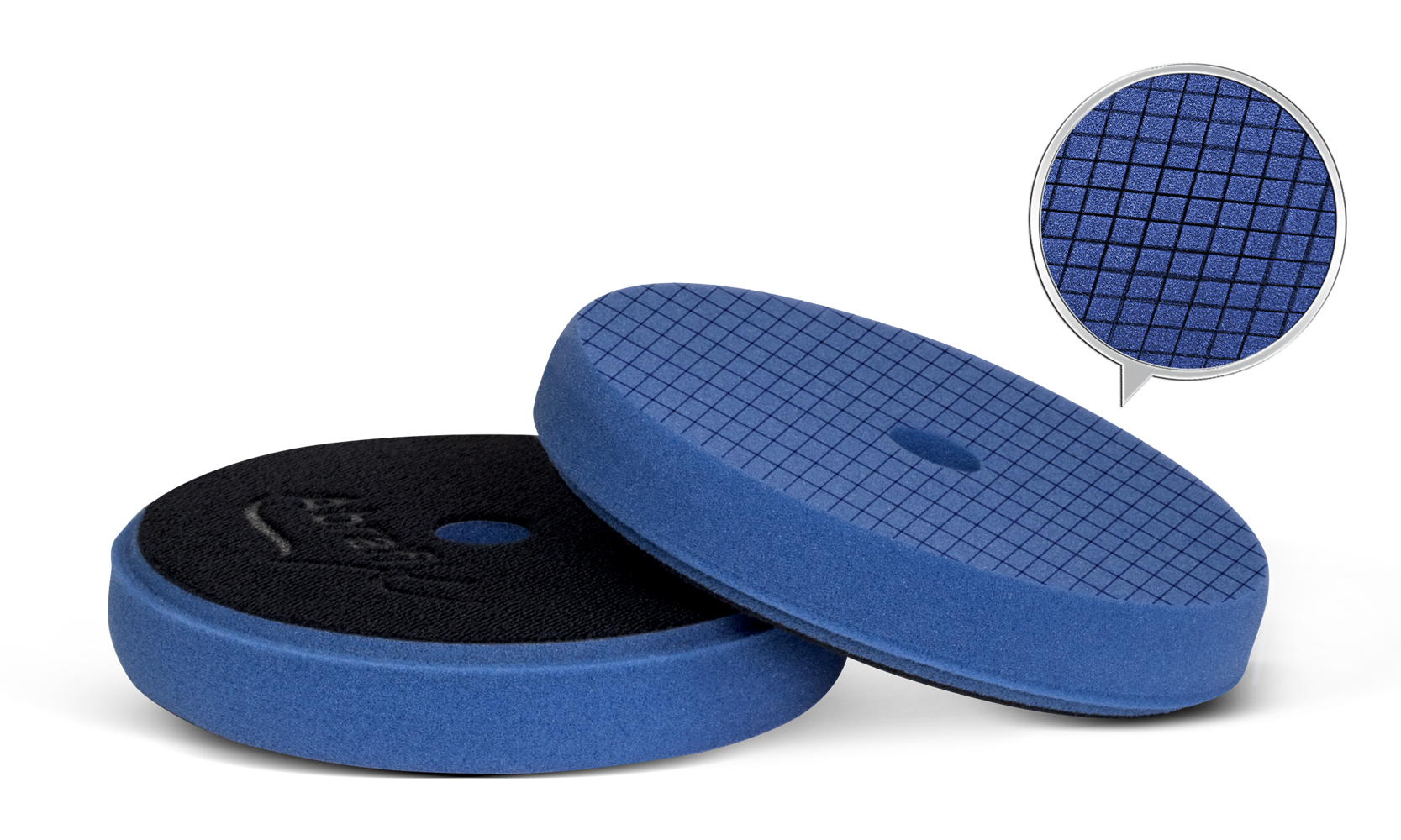

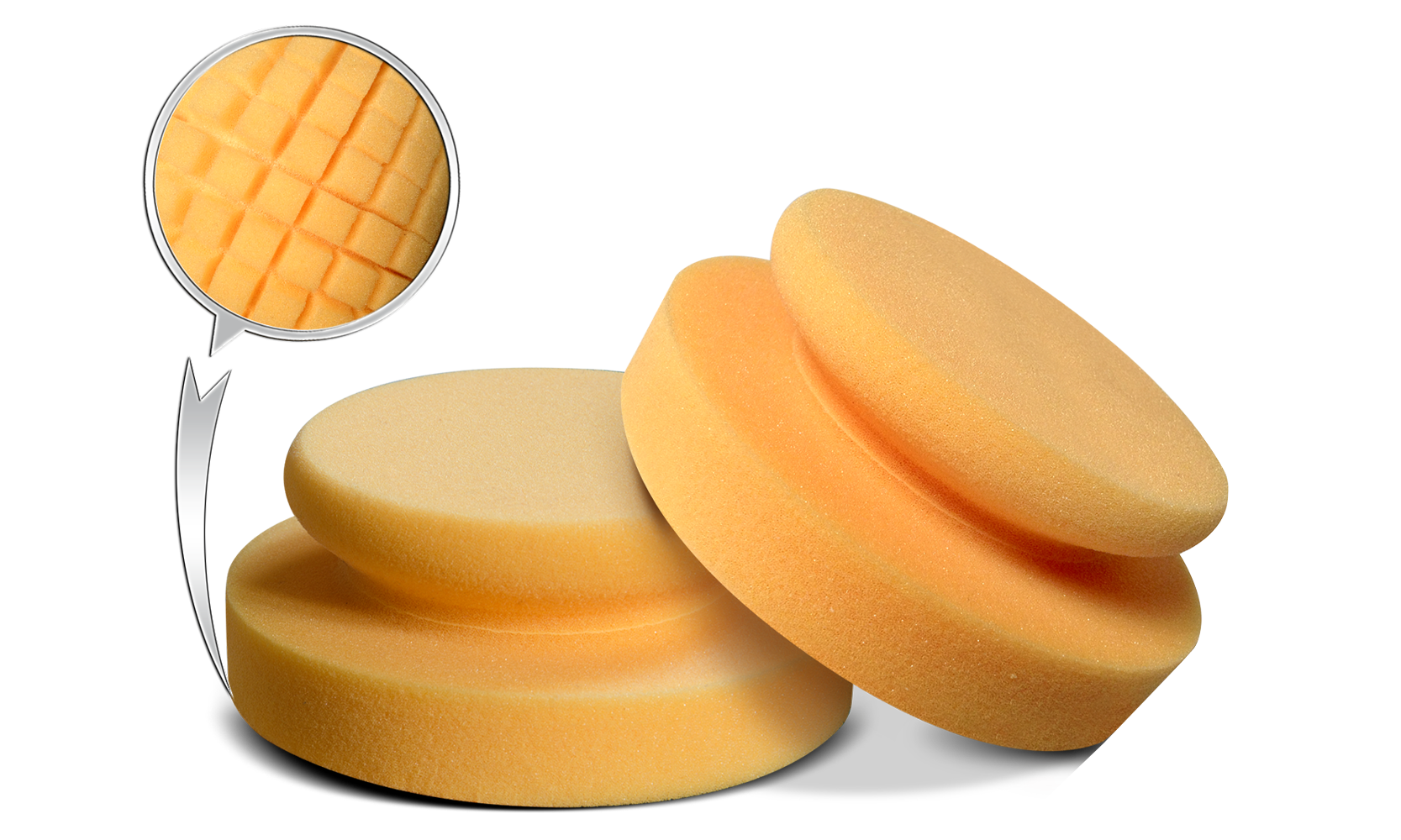

Opened in 2007, our pad manufacturing facility plays a key role in the design and production of an extensive range of high-tech, top-quality polishing pads. During the past two years, we have continued upgrading our pad manufacturing facility, both by implementing new systems aswell as by optimising existing ones. A computer-controlled SpiderPad calibration machine, a fully automated high-frequency milling system with an integrated packaging line and a high performance die-cutter are among the latest and most important machineries in which we have invested.

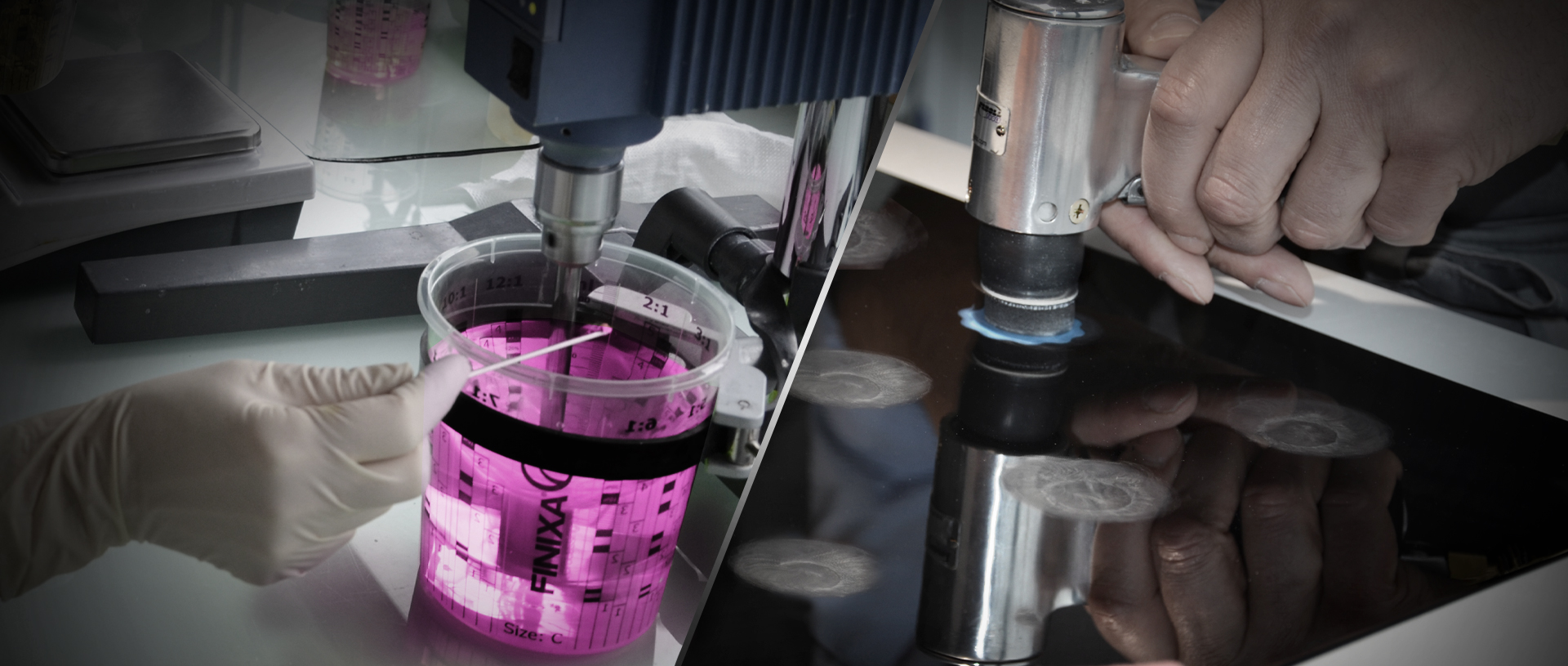

ROUND-THE-CLOCK RESEARCH AND DEVELOPMENT

Our core area of expertise includes developing unique High Performance Compounds. Innovations like the highly abrasive single-step compound S3 Gold have played an important role in setting new standards in the paint refinish market. The new S20 Black compound will revolutionise the detailing of used paint surfaces. Our dedicated team of product developers and application engineers have taken on the ambitious task of developing the most innovative, exceptional and efficient rubbing compounds. Don ́t take our word for it and just give the “Abrafix“ compounds a try.

GERMAN EFFICIENCY

The majority of our polishing pads are manufactured for industrial paint finish applications in modern car plants. Distinctive cost awareness among our industrial clients, and the high quality standard expected from our pads, have had a lasting impact in shaping our manufacturing processes. Currently, our facilities have a maximum daily production capacity of 10,000 polishing pads. Customers from all over the world recognize and appreciate our pads “Made in Germany”.

PREMIUM PRODUCTS

Our corporate culture focuses on providing premium products and services. To implement this strategy, we pursue an integrated approach. High-grade, innovative and unique products and ideas can only develop when this philosophy is an integral part of our corporate culture and all processes, facilities and equipment are geared to meet the highest quality demands. Thanks to their distinctive brand names, among other features, our pre- mium products are easily identifiable and enjoy a high level of awareness.

A-ONE-STOP-SHOP

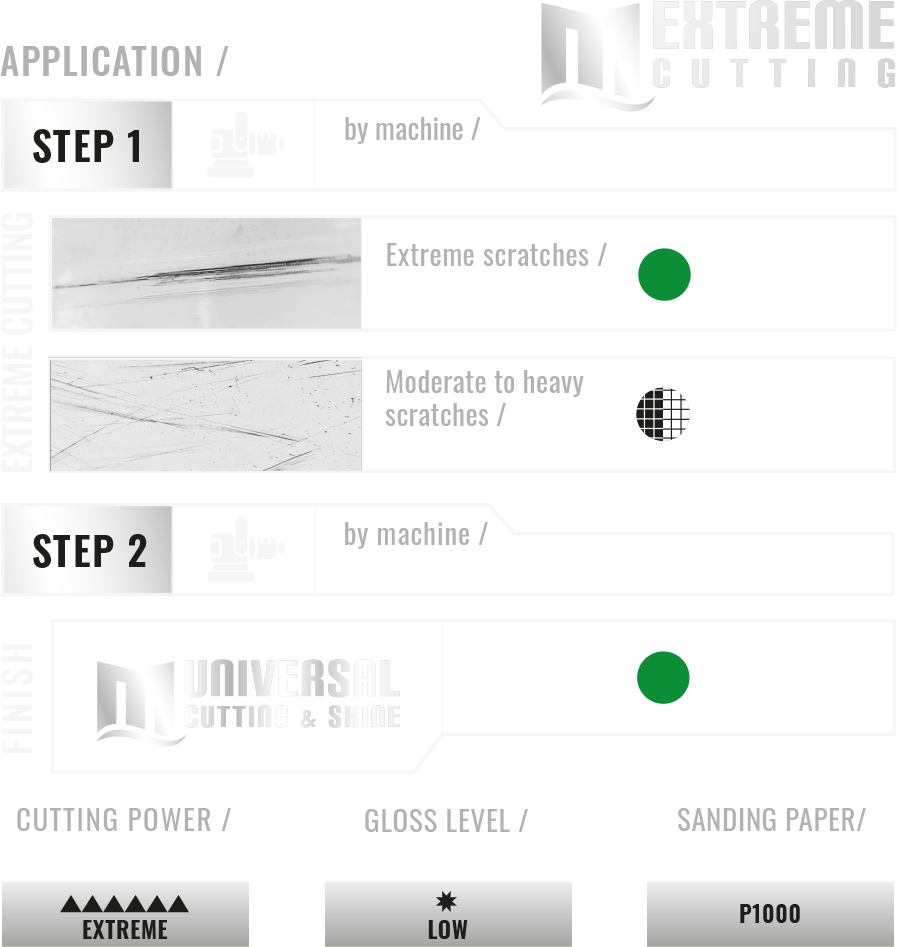

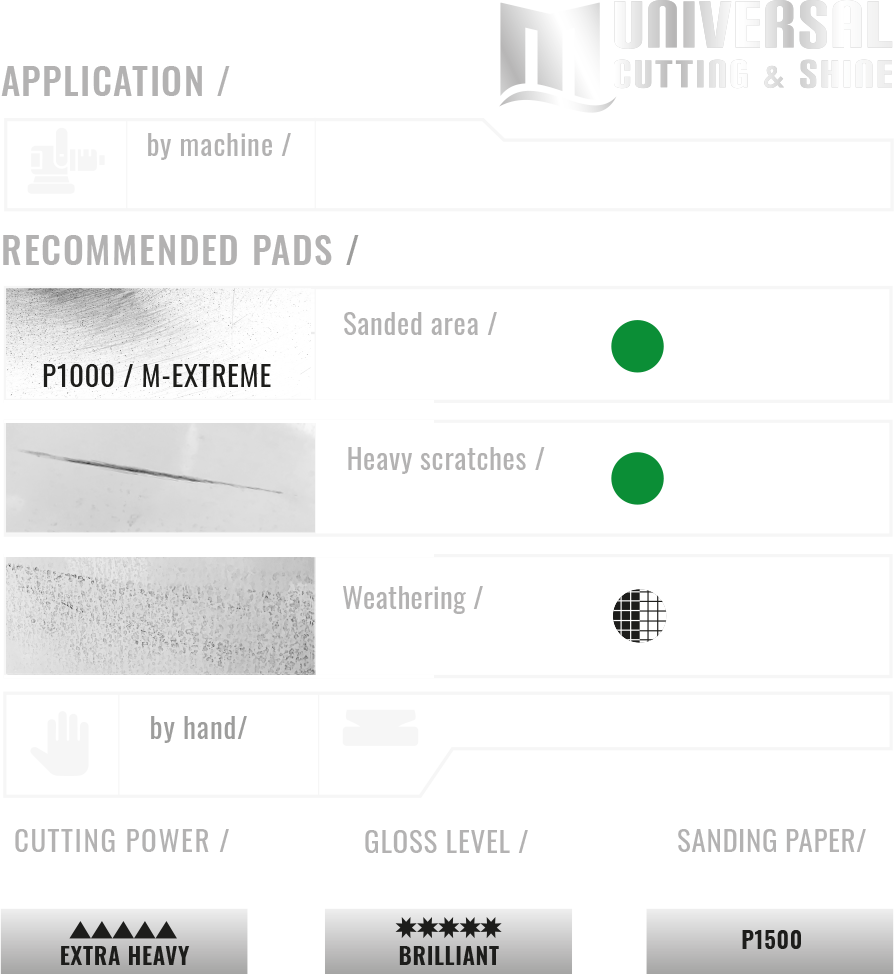

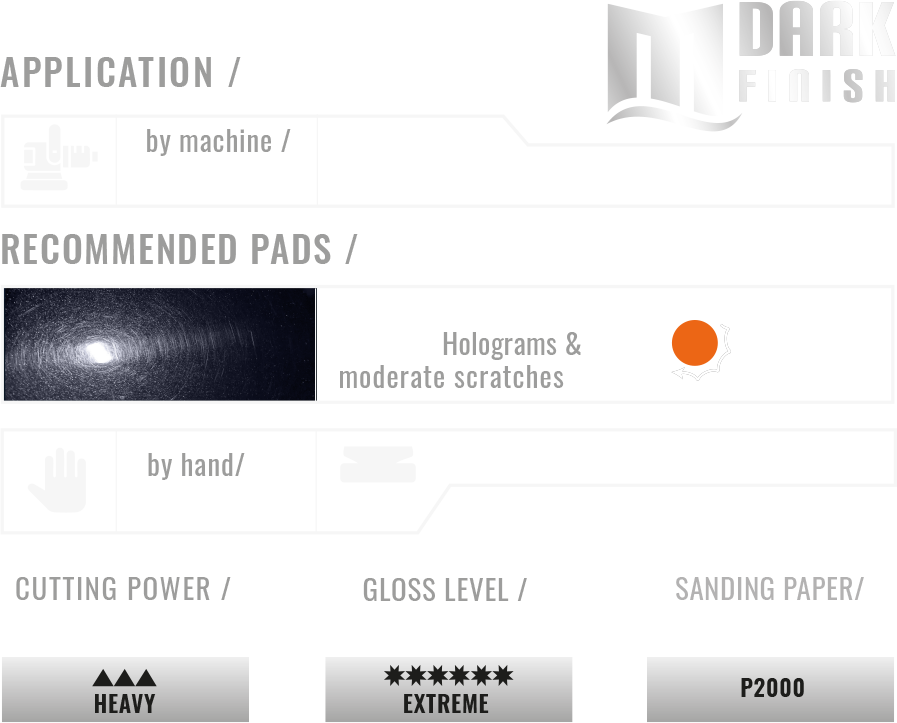

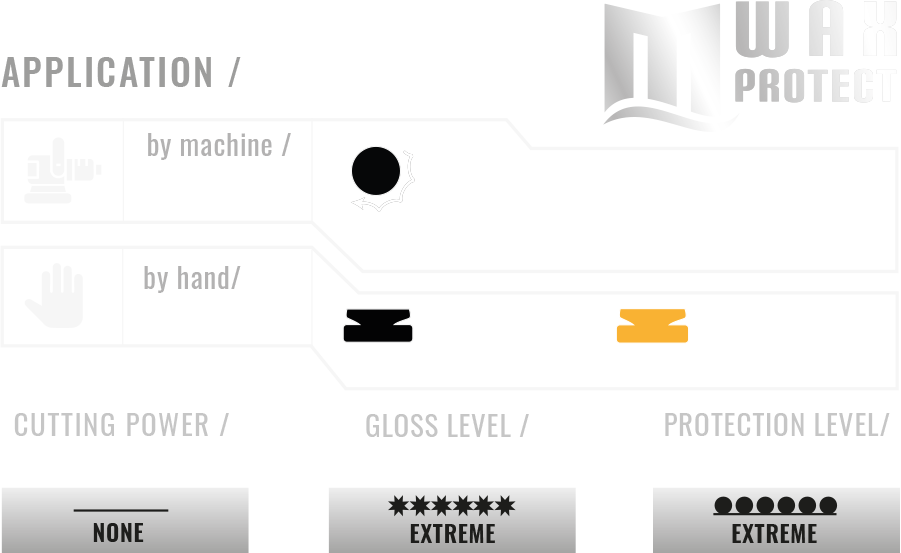

Like clockwork, our comprehensive paint finish solutions are perfectly matched to complement one another. Nothing is left to chance when it comes to the applications of our products. To guarantee a perfect and flawless finish, we provide our customers with the matching pad for each polishing compound. Please refer to the following charts for details on the appropriate polish and pad combinations.

STATE-OF-THE-ART MACHINES FOR 100% QUALITY

The machinery used in our manufacturing systems is just as unique as our products. Across the world, there is probably no other manufacturer who possesses a production unit capable of manufacturing such an extensive range of high-grade products that include polishing pads and compounds meeting the highest standards. To satisfy the ever increasing demand for our products, we have upgraded almost our entire manufacturing systems and, in addition, we have invested hugely in modular, multi-purpose production lines.